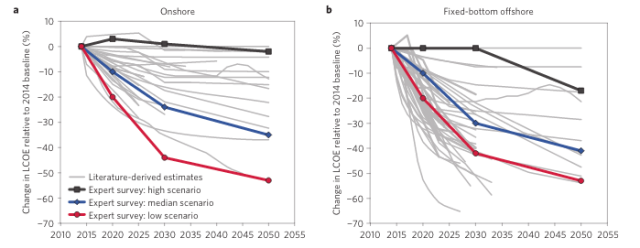

A paper published in Nature Energy analyzed the opinions of 163 wind power experts from around the globe and found that they expect the cost of wind energy to fall even further. Those experts said that by 2030, both onshore and offshore wind turbines will get bigger, leading to additional cost reductions and smoother energy generation.

The median response from experts was that wind power cost could be reduced by 24 to 30 percent by 2030 based on the advances in turbine technology that are either projected or already being seen today.The authors of the study also acknowledge that estimates about wind power cost reductions have generally been conservative in the past—today in some areas wind energy is already competitive with fossil fuels.

The study was conducted by researchers from Berkeley Lab, the National Renewable Energy Laboratory (NREL), University of Massachusetts, and participants in the IEA Wind Technology Collaboration Programme Task 26. They gathered information from experts providing basic “learning curve” assessments based on previous growth and cost projections, as well as engineering assessments that involve “detailed modeling of specific technology advancements.” The engineering assessments are less common than other kinds of forecasts due to the detail and cost they require to complete.

The survey, which the paper suggests is the largest of its kind to date, came up with some interesting numbers.

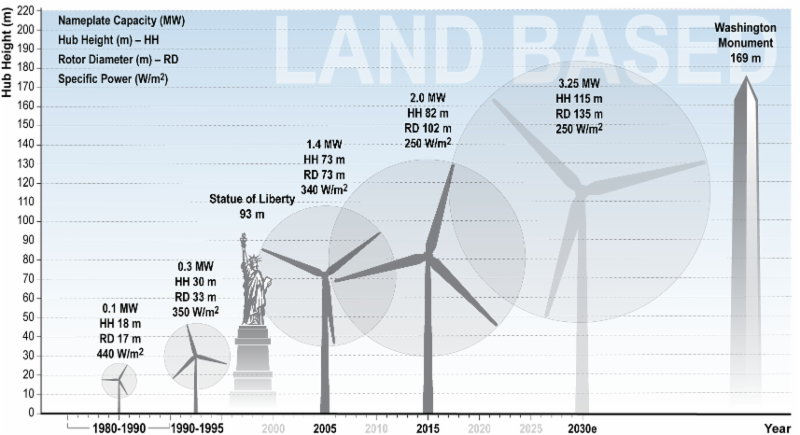

In 2015, onshore wind turbines averaged a hub height of 82m, a rotor diameter of 102m, and a power output of 2 MW. In 2030, experts on average suggest that onshore wind turbines will have a hub height of 115m, a rotor diameter of 135m, and a power output of 3.25 MW.

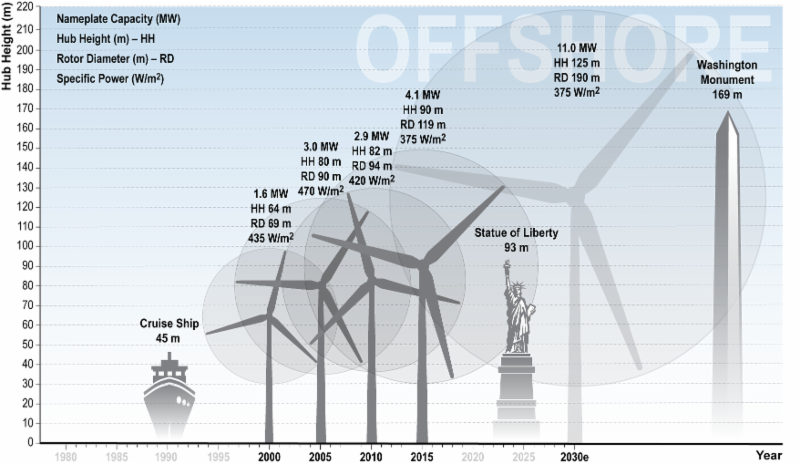

Offshore, the story is more dramatic. Where today’s turbines have a hub height of 90m, a rotor diameter of 119m, and a power output of 4.1 MW on average, 2030’s offshore wind turbines will measure 125m and 190m in hub height and rotor diameter, respectively, and output an insane 11 MW on average—each.

As each turbine gets bigger and produces more energy, the cost of building that turbine will be easier to offset by the power it produces.

The paper’s authors note that currently wind power is supplying 4.3 percent of the world’s power supply, up from less than 1 percent in 2006. The increase in supply was assisted by regulatory policies, but recently wind power infrastructure has become increasingly viable due to technology advancements and economies of scale. With recent global efforts to fight climate change, organizations like the International Energy Agency and Global Wind Energy Council have suggested that by 2040, 6 to 15 percent of global energy production could come from wind, and in 2050 that number could be 17 to 31 percent.

In 2015, a paper from the Department of Energy (DOE) suggested that increasing rotor diameter and height is the best way to access more power from wind turbines, even in areas with lower wind speeds. This is where offshore turbines could come in. Although they currently only account for a little under three percent of wind power capacity due to the extraordinary cost of installing stationary turbines with cables running to shore, as turbine technology improves, it’s easier to transport very large blades to sea-based locations than it is to find routes to land-based sites that can be accessed by truck without any curves in the road or bridges that could hinder the journey.

The authors add that most offshore wind projects being built today will have turbines with a 6-8 MW capacity, and that larger capacity is driven by necessity as much as technological advancement—because the costs of building offshore projects is so large, suppliers are driven to seek the highest power-producing hardware they can find.

Still, the authors caution that historical data for offshore wind power sites is not as robust as that for onshore wind power, and that could lead to some variability in the cost of such wind projects. The experts surveyed generally agreed that the number one way to improve the cost of offshore wind projects is to reduce upfront costs, which includes building substructures and foundations for the turbines.

Berkeley Lab also suggests that there could be additional benefits to turbines growing larger, in that bigger turbines could also contribute to steadier power output if they’re capable of rotating at lower wind speeds. “Work by and for the U.S. Department of Energy, meanwhile, shows how larger turbines and turbine design advancements might unlock new areas for wind development, both on land and offshore, that would otherwise be deemed unattractive,” the Lab writes.

The one area of contention the researchers encountered, however, was how big a turbine has to be before increasing its size becomes uneconomic. “[S]ome experts anticipate that smaller machines will be more common, while others expect that still-larger turbines will dominate the market,” the researchers write.

Nature Energy, 2016. DOI: doi:10.1038/nenergy.2016.135 (About DOIs).

reader comments

222